AI Revolution in the Electronics Industry with LAIDFU: Your User-Configurable AI Agent

Customer Service Monitoring

Compliance and customer responsiveness are critical elements in the electronics market, where consumer satisfaction is paramount. LAIDFU, a sophisticated AI Agent developed by Multiable, helps management assess customer service operations with minimal supervision. By leveraging AI technology, including tools like ChatGPT, LAIDFU highlights potential pitfalls in customer interactions and streamlines the monitoring process. Additionally, it significantly reduces labor costs typically associated with traditional Customer Relationship Management (CRM) systems by minimizing data input requirements. For example, a company dealing in consumer electronics can utilize LAIDFU to ensure their customer support interactions meet compliance standards while also providing rapid responses to customer inquiries.

Recurring Income Boost by AI

One common challenge in the electronics sector is that after-sales staff may struggle to identify upsell opportunities. LAIDFU addresses this issue adeptly through its intelligent features. By integrating AI capabilities, LAIDFU proactively identifies potential upsell scenarios and assigns capable staff to follow-up efforts. The entire process is conveniently monitored by management, ensuring that no potential revenue is missed. For instance, an electronics retailer can use LAIDFU to identify when a customer who purchased a smart TV might be interested in home theater accessories, thus enhancing the overall customer experience while boosting sales.

Crisis Management by AI

In the fast-paced electronics industry, anticipating crises can determine a company’s long-term success. LAIDFU excels in this area by continuously monitoring customer behaviors without requiring human supervision or additional data input. Should a potential crisis scenario arise—such as a surge in negative feedback on a newly released product—LAIDFU immediately alerts management. This proactive stance empowers companies to address issues before they escalate, ensuring sustained customer loyalty and brand reputation.

As a user-configurable AI Agent, LAIDFU empowers businesses in the electronics sector without requiring expertise in AI or IT, resulting in low implementation costs while maximizing operational efficiency. From enhancing sales performance to streamlining customer service, LAIDFU stands out as an invaluable tool for future-ready electronics companies.

Effective Prospect Allocation

In the highly competitive electronics industry, companies invest substantial marketing budgets to enhance brand awareness and identify potential customers. However, these efforts can be undermined by underperforming sales personnel. Enter LAIDFU, your user-configurable AI Agent that identifies the weakest links within sales teams. By enabling management to quickly recognize underperforming sales staff, LAIDFU facilitates timely replacements with more competent individuals. This proactive approach minimizes the risk of lost deals due to controllable human factors, allowing companies to utilize their resources more effectively for prospect allocation.

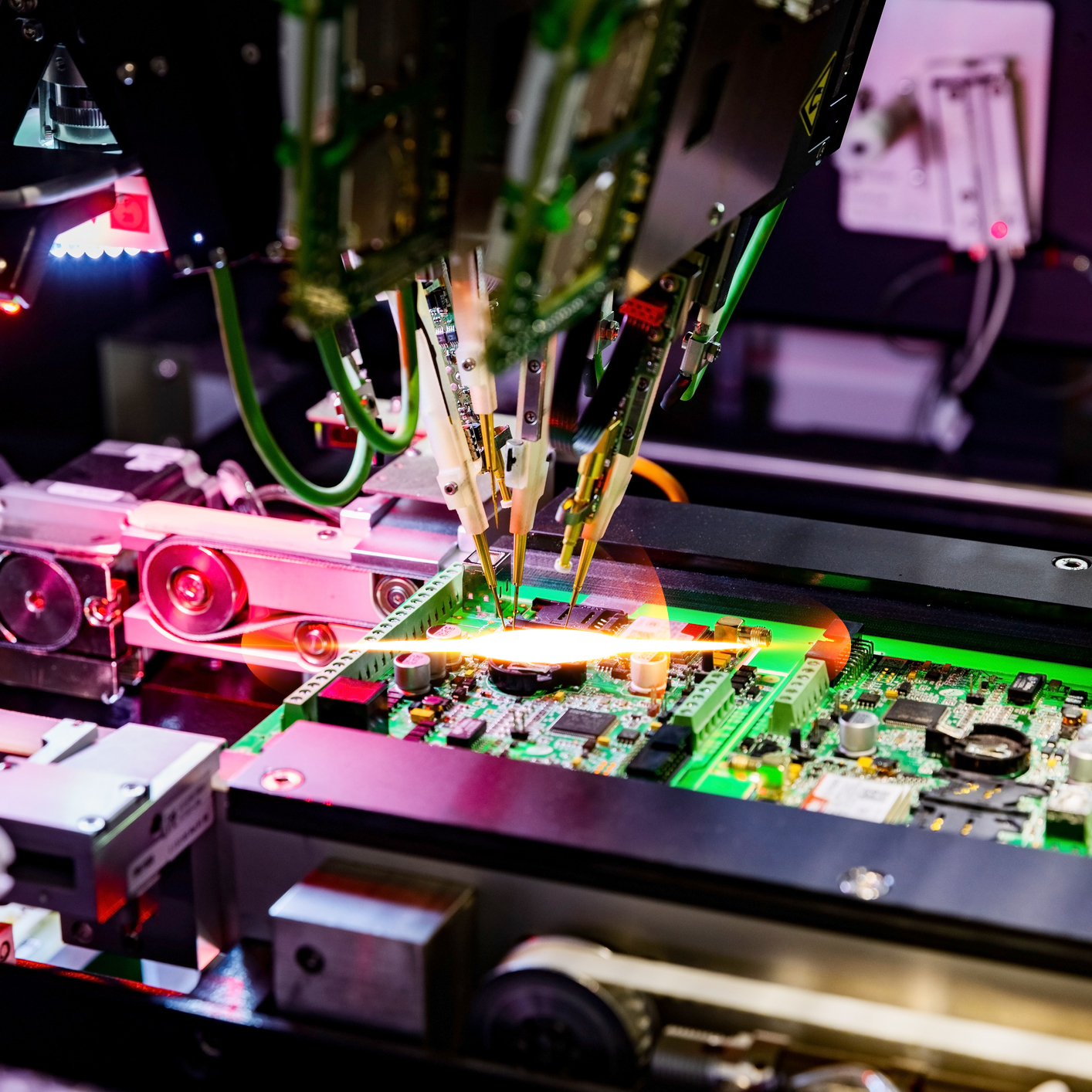

Flexible BOM and Re-scheduling Management:

In order to manage the large amount of alternative materials and the changeable production schedule for electronics industry, aiM18 ERP provides a professional and exhaustive solution which empowers unlimited level BOM with routing and advanced scheduling management for enterprise to monitor the entire production process, for example:

- the amount of used alternative materials,

- the wear and tear of alternative materials,

- the change of the production schedule,

- the change of the production process, etc.

The unlimited level of BOM feature has even been recognised for its uniqueness and robust architecture. By providing comprehensive and digitalised monitoring with integration of BOM and production routing, aiM18 ERP sends reminder to different department automatically to ensure the changes are notified to every parties efficiently as to improve the collaboration of different parties, reduce the duplicated data input and increase data accuracy.

Production Schedule Optimisation:

Robust aiM18 ERP production module generates structured and precise production scheduling based on processing time and accurate deadlines for each machines/ work centre/ working progress/ shift. Collaborated with the workload data, the production schedule is generated automatically in order to increase the efficiency in scheduling and avoid overscheduling due to employee theft and administrative losses. In addition with automatic reminder function, enterprise will be acknowledged once there is abnormal situation on the production progress. Then, enterprise can solve the abnormality immediately and reduce the time wasted in discovering problem manually. To achieve the efficient “plan-execute-monitor-feedback” digitalise management for a better productivity, aiM18 ERP is one of your best choices.

Precise Lot Number Control:

Enterprise can monitor the production procedure in every progress by aiM18 ERP precise lot number control. Lot number control can be defined for materials/semi-finished product/ finished product, etc. Enterprise may check the status on every item which has lot number, including:

- Material Picking,

- Subcontract Picking,

- Production Material Returning,

- Inbound of Semi-finished Product,

- Inbound of Product,

- Dispatch,

- Refund, etc.

aiM18 ERP lot number control assists enterprise to track down the problematic material/ semi-finished product/ finished product in an easier way. Under precise lot number control, enterprise will notice:

- which product is produced by which batch of materials,

- who is responsible for producing that product,

- which supplier provided that component, etc.

It increases the efficiency for enterprise to address sudden issue like the collection for problematic material, etc.

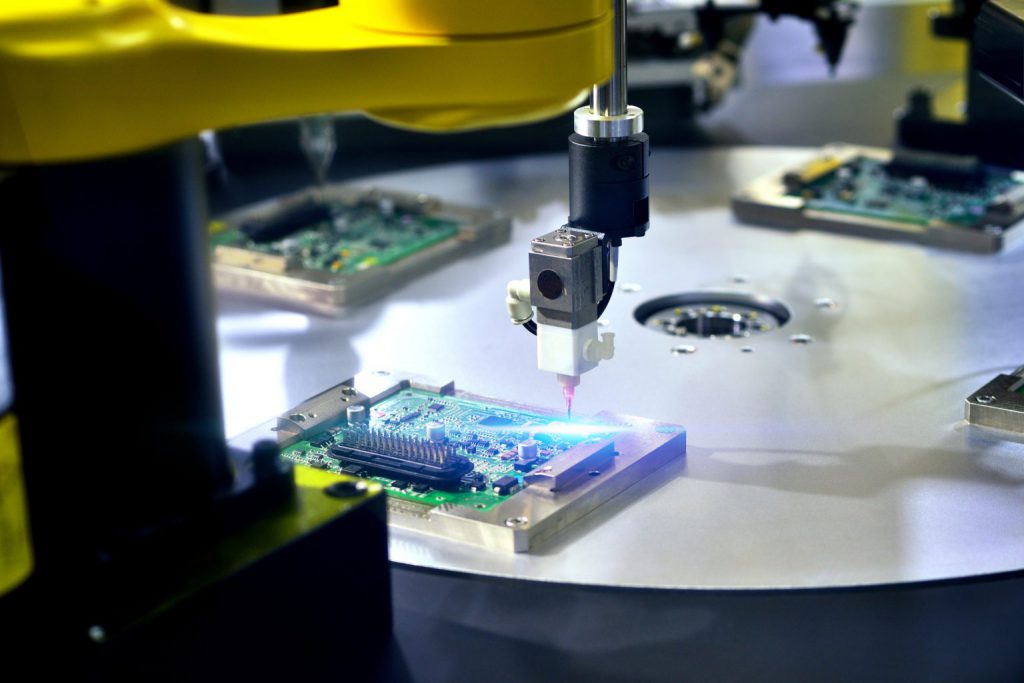

Intelligent Multi-unit in Single Item:

Multiable understands there are different units used to communicate within different departments in electronics industry. Hence, multi-unit calculation and conversion feature for the same product, material, semi-finished product, such as piece, KG, box, etc. should be highlighted. It definitely enhances the communication between different departments to perform a better efficiency and productivity and assists enterprise in business expansion and growth.

Accurate Material Management through ERP Integration:

The scalable aiM18 production module seamlessly collaborate with powerful bill of materials based on enterprise actual status, such as the amount of available machine, production index, etc. to calculation needed materials for each production order. With the flexible material picking management, enterprises can define appropriate picking method based on practical situation, such as order picking, batch/ consolidated picking, back flushing, etc. aiM18 production module monitors the entire manufacturing process, starting from picking materials to production and dispatch which minimise the waste and cost of materials and improve the accuracy of material cost calculation.

Major ERP Functions for Electronics Industry

Lot Number Control

Work Centre Allocation

Build-in AQL

Bill of Materials

Quality Control Management

Production Job Re-scheduling

Production Process Scheduling

Inventory Management

Master Production Scheduling

Work Process Complete Management

Production Subcontracting

Subcontracting Quality Control

Subcontracting Purchasing Management

Subcontracting Refund Management

Labour Cost Calculation (per PCS/ Working Hour)

Advanced Planning and Scheduling (APS)

Material Requirement Planning (MRP)

Solutions of Electronics Industry

- Graphical User Interface

- Flexible User-defined Set Up with No Code Approach

- Routing

- Lot Number Control

- Unlimited Field and Form Editing

- Unlimited User-defined Module

- Production KPI Setup

- Production Process Condition

- Product/ Semi-finished Product/ Subcontracting Multi-unit Switching

- Step-wise Approach Consumption Management

- Quality Control Methodology (Sampling Inspection, Full Inspection or Exemption)

- Labour Cost (Individual/ Group) Calculation per PCS / Working Hour

- Capacity Requirement Planning

- Bill of Materials

- Native Mobile App

- Workflow Approval & Review

- Conduct Analysis on Production Report

- MRP (Material Requirement Planning)

- Leverage the configurable BOM to adjust material needs intelligently based on customised needs in various orders

- MRP Lab, a unique production control function in aiM18, allows PMC to perform numerous what-if analysis before MRP execution

- MRP system fully integrates with inventory control system, MES system and production cost system