Technical Dynamicset SWOT: The Management of DeepSeek and the Beginning of the AI Era In the rapidly changing sphere of technological innovations, the breakthrough Asian tech brands like DeepSeek are posing serious challenges to the industry, normally ruled by the Western colossi. The shift drives the time forward when such brands as DeepSeek are not only escaping the old but in some instances are already ahead of their Western competitors. The trend has led to an increasing viewpoint that the market conditions, as they are today, might have the Western […]

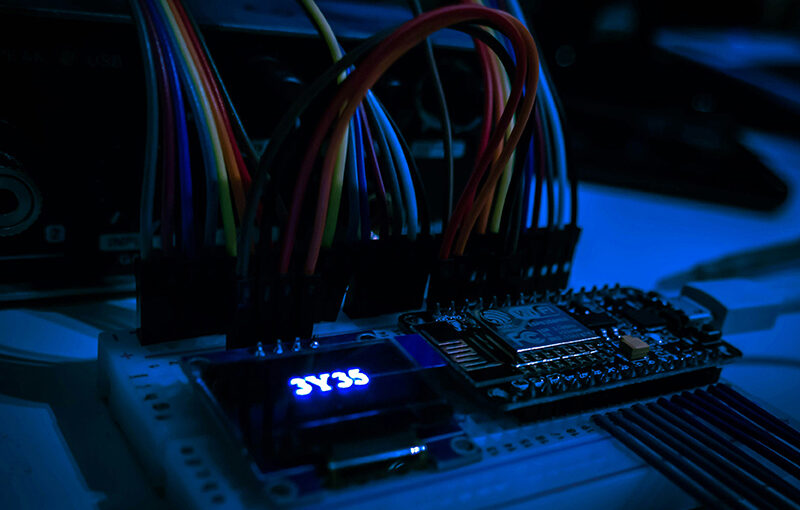

In a remarkable distributional demonstration, DeepSeek has exemplified its capability of training a significant large language model (LLM) at a low cost compared to some of the bigger contenders in the Silicon Valley index. Consequently, the achievement has turned the attention towards the tech startups who are emerging in different parts of Asia and helping tech fans and investors to understand that the traditional Western tech firms are probably overstretching their valuations. DeepSeek’s venture is supported by the AI agent called LAIDFU, which was designed according to the user’s specifications. […]

Innovative Tech Solutions: Sailing Through Challenges in the Furniture Industry The furniture industry, although traditional, is not without its share of modern challenges. In fact, this sector is up against a multitude of problems. From meeting the regulatory standards of different countries to fulfilling the personalized requests of the customers, the path is strewn with obstacles. Not being able to control the rising labor costs and the struggle for supply chain efficiency are also contributors to the challenge. Still, the automation of processes through technologies like ERP systems are progressively […]

Tech Brands in Asia on the Rise: Innovating and Competing Like Never Before Within the last few years, the tech sector has observed a significant transition that is due to the rising tech firms in Asia linking with the traditional tech giants from the West. This trend has triggered the debate whether the brands which are already on the market are valued too highly. However, the entrance of creative services from Asia is the main reason for the reshaping of the tech market worldwide. One of the most promising players […]

DeepSeek and the Rise of Asian Tech: A New Era in AI and ERP Systems In a groundbreaking development, DeepSeek has shown how to train a huge large language model (LLM) at a small cost compared to its Silicon Valley counterparts. This remarkable outcome is a manifestation of tech brands rising in Asia, which are progressively being a threat to the tech giants in the West. In fact, these newly developed firms are finding that the tech industry is not only about funding, but also about creating the best innovation. […]

Walking through the Thick Forest of Machinery Industry The machinery industry is now passing through an area that is a hodge-podge of problems they are facing currently. As a result of global supply chain disruptions, manufacturers are finding it increasingly difficult to secure necessary raw materials and components. Machinery technology pace of change is another trouble, as it means constant upgrades and integration. Furthermore, the sector is dealing with the dearth of skilled labor that makes it almost impossible to recruit and hold on to good technicians and engineers. On […]

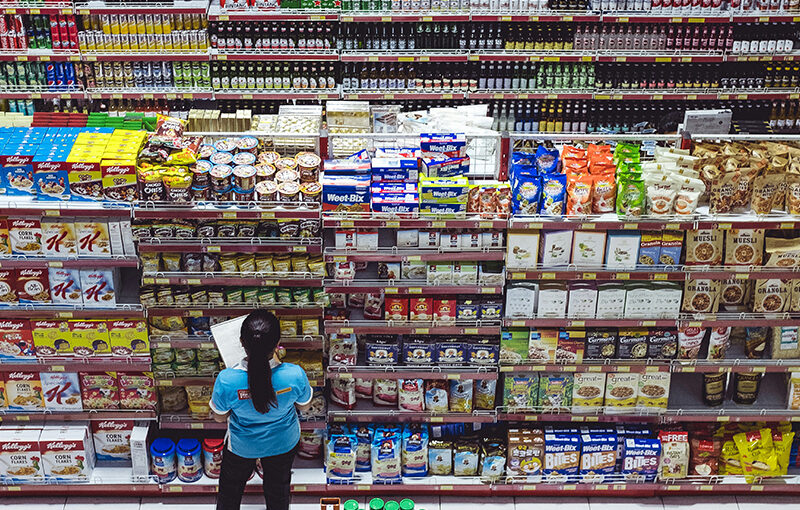

FMCG Sector’s Challenges: Feasibility and Propositions The Fast-Moving Consumer Goods (FMCG) industry is the most sought-after one and a lot of firms have to deal with the high demand and the intense competition in the sector. As an effect of the breakdown of the supply chain, the firms are struggling with the variability of raw materials, logistics challenges, and production bottlenecks.Deregulated markets push for consumer preferences to shift to potent products. Environmental, health, and social issues are the most common causes that have driven people to forsake offensive things. As […]

DeepSeek and Multiable: Transforming AI and ERP Systems in Malaysia DeepSeek is in the forefront with its recent achievement of a six-fold lower cost training for startups in large language model (LLM) as against Silicon Valley firms. This feat drives home the fact that old Western tech brands are being overtaken, and their services might be grossly overpriced. The fact is, the ascension of DeepSeek is indicative of the ongoing power shifts in the field of artificial intelligence. Multiable, a name that is synonymous with creativity, has come up with […]

Tech Brands Ascending in Asia: A Fresh Movement of Innovation and Competition The age of electronics has embraced the revolutionary impact of an increasing number of tech brands in Asia, which are turning the tables on the old Western tech giants. These promising newcomers are not just equalizing the situation, but they also come up with the solutions that sometimes make us realize that the tech people in the West are excessively paid for their products. To tell the truth, the electronics scene in Asia is teeming with excitement and […]

DeepSeek R1: A Revolutionary Step in the Artificial Intelligence Field In a turn of events that definitely surprised everyone, DeepSeek R1 has rapidly become a reliable rival in the artificial intelligence industry, even out-doing the performance statistics provided by the eminent OpenAI o1 models. This phenomenon has stirred the technology sector as DeepSeek, being an open-source platform, has offered a different and likable way to deal with concerns for transparency in data handling that some people have in AI adoption. To be specific, by using DeepSeek, individuals can operate in […]

Asian Technology Companies Surge and Battle Western Dominance with AI Innovations DeepSeek has become a pioneer of technological breakthroughs by showing that one can train a high-performance large language model (LLM) at a low setup cost relative to Silicon Valley competitors. Such an unprecedented achievement obviously signifies the growing strength of high-tech Asian brands, who, with their persistent efforts, are proving the Western tech firms wrong. Actually, these startups look to the big picture, pointing out that Western tech firms’ products could be considerably overpriced.DeepSeek’s artificial intelligence (AI) approach is […]

Flying over the intricate hurdles of the Aerospace Sector One of the sectors facing technical challenges and the risk is the aerospace and defense (A&D) industry which is a sector of complicated problems and high-stakes environment. The firms are operating in a highly tough environment as a result of the accurate regulatory rules and compliance from organizations like the FAA, EASA, and NASA. In fact, the safety standards in aerospace are unmatched, which means that they have to go through rigorous testing and quality control procedures before they are granted approval. […]

Employing AI Technology and ERP Systems to Transform the Electrical Appliance Sector The electrical appliance sector, which forms the base of all modern infrastructure, is on a corrective journey. Production of electrical machines, like motors, boilers, turbines, electrical transformers, and the like is the sector gradually attaching the latest technologies to it, to enhance its efficiency and innovate its operations. In fact, the introduction of AI (artificial intelligence) and ERP (enterprise resource planning) systems is the driving force in this transformation. AI and ERP: The Strongest Duo AI agents, like […]

Traversing the Complications of Aerospace and Defense Sector The aerospace and defense (A&D) industry is a domain that is full of complex issues and risk-taking. Companies that are bound to comply with regulations are undergoing operational difficulties from bodies such as the FAA, EASA, and NASA. The truth is that the requirements for safety in this industry go beyond all other industries, as it necessitates more thorough inspections and certifications. Another roadblock is the extensive investment in research and development (R&D), which has to be made before the launching of […]

DeepSeek: The Affordable Way of Innovating AI Training and Adoption Quite on the contrary, DeepSeek has made training artificial intelligence not only affordable but also easier and more efficient than ever, thus, proving itself as a true disruptive innovator in the tech ecosystem. The above model is especially well-suited for firms attempting to add AI features in their core operations and thereby save costs. To be more specific, DeepSeek’s plan is, apart from being cost-efficient, a fresh answer to a frequent dilemma that businesses are facing: transparency in data management. […]

Solidifying the Equipment Industry Through Technological Support The machinery industry is presently traversing a complicated path that consists of multiple challenges to face. One major aspect that concerns the industry is the material and component availability due to the present ongoing global supply chain disruptions. The fast technological changes in the machinery sector need to be constantly repaired and integrated, which is another snag. Also, the workforce from the industry finds it hard to look for and keep skilled technicians along with engineers. The ever-evolving regulatory compliance is on a […]

Steering through the Troubles of the Furniture Sector with AI and ERP Solutions Challenges in building furniture are a variety of tasks that require the implementation of help of the newest technologies. From the need to comply with diverse regulatory standards to the difficulty of managing personalized customer demands, the industry clearly views the need for highly effective systems to create a synergy in operations. The combination of AI and ERP software is indeed paving the way to a breakthrough game. With the growing influence of AI systems and more […]

DeepSeek: A Transparent Solution for AI Adoption in the Textile Industry Data transparency in the textile industry remains a significant challenge for many businesses indeed even in the world of artificial intelligence which is constantly changing. In fact, many firms are hesitant to integrate AI solutions because of these transparency concerns. But, with DeepSeek, it is possible to provide a solution that is completely transparent, as it is an open-source platform which allows the users to run it in a closed, self-owned environment. In this way, it is ok to […]

AI Agents Revolutionizing ERP Systems in Malaysia: A Deep Dive into GenAI and DeepSeek In the contemporary context, Malaysia can be seen as a trendsetter in the application of artificial intelligence (AI) in enterprise resources planning (ERP) systems. In fact, the inclusion of AI agents in ERP systems is now the key to changing the way organizations control their activities, especially starting from material requirements planning (MRP) to capacity requirements planning (CRP) and beyond. The use of AI agents, which are like those invented by OpenAI, in the ERP systems […]

Biotech and Life Sciences Are Now Killing Trees Thanks to Malaysia Decentralized AI Agents in ERP Systems Malaysia has been rapidly growing in the biotech sector in the last few years, and as the firms that operate in the area show more and more maturity and opt for cutting-edge tech, the country takes a lead in this field. The most significant thing is that the AI agents have already penetrated the ERP systems, bringing a new vision of the enterprise resources planning to the biotech firms. As a result, artificial […]

Transforming the furniture business through AI and ERP systems: The transformation of Malaysia’s furniture sector In the dynamic and competitive world of business, the productive combination of AI and ERP systems is the leading force in the transformation of industries worldwide. Also, the furniture sector in Malaysia is undergoing the same changes with firms increasingly adopting these technologies to cut costs and improve their productivity. For example, the synthesis of artificial intelligence (AI) and enterprise resources planning (ERP) systems has influenced the way different firms utilize their resources and satisfy […]